- Exit 15, Eastern Ring Road, Prince Saad bin Abdulrahman Road, Plaza Complex, Second Floor, Office 8

- info@activeguard.site

Exit 15, Eastern Ring Road, Prince Saad bin Abdulrahman Road, Plaza Complex, Second Floor, Office 8

0543804776

info@activeguard.site

by activeGuard

by activeGuard 1. Natural Ventilation

Relies on natural differences in temperature and air pressure. When outside air is cooler than inside air, the warm air rises, creating a vacuum that allows cooler air to enter through windows and lower openings, promoting natural airflow.

2. Mechanical Ventilation

Relies entirely on fans and electrical equipment to facilitate the circulation of fresh air. These systems control temperature and excess humidity and remove polluted air and odors in a balanced way. Some systems include units to recover lost energy by exchanging heat between incoming and outgoing air, improving energy efficiency.

3. Mixed-Mode Ventilation

Combines natural and mechanical ventilation techniques to achieve optimal performance in improving air quality. These systems aim to leverage the advantages of both types to provide a comfortable and healthy indoor environment while achieving good energy efficiency.

4. Spot Ventilation (Localized Extraction)

Focuses on removing pollutants from specific sources. Common examples include exhaust fans in modern bathrooms that expel humidity, and kitchen hoods that remove cooking fumes. Extraction fans can also serve multiple rooms in a central extraction system.

5. Balanced Central Ventilation

Operates with high efficiency thanks to two fans and two ducts. One fan and duct remove pollutants from the indoor air, while the other fan and duct introduce fresh air into the building. The incoming outdoor air is filtered using special filters before distribution.

1. Needs Assessment

Evaluate the size of the space and the volume of air requiring extraction to ensure adequate ventilation.

Determine the appropriate type of extraction fan based on the intended use (e.g., for kitchens, bathrooms, or industrial spaces).

2. Site Selection

The fan location must be optimal for efficient air removal without obstructions.

Ensure sufficient space is available for the necessary ducts and connections.

3. Engineering Design

Design the ductwork system connecting the fan to external vents.

Ensure the system is designed to minimize air resistance and maximize extraction efficiency.

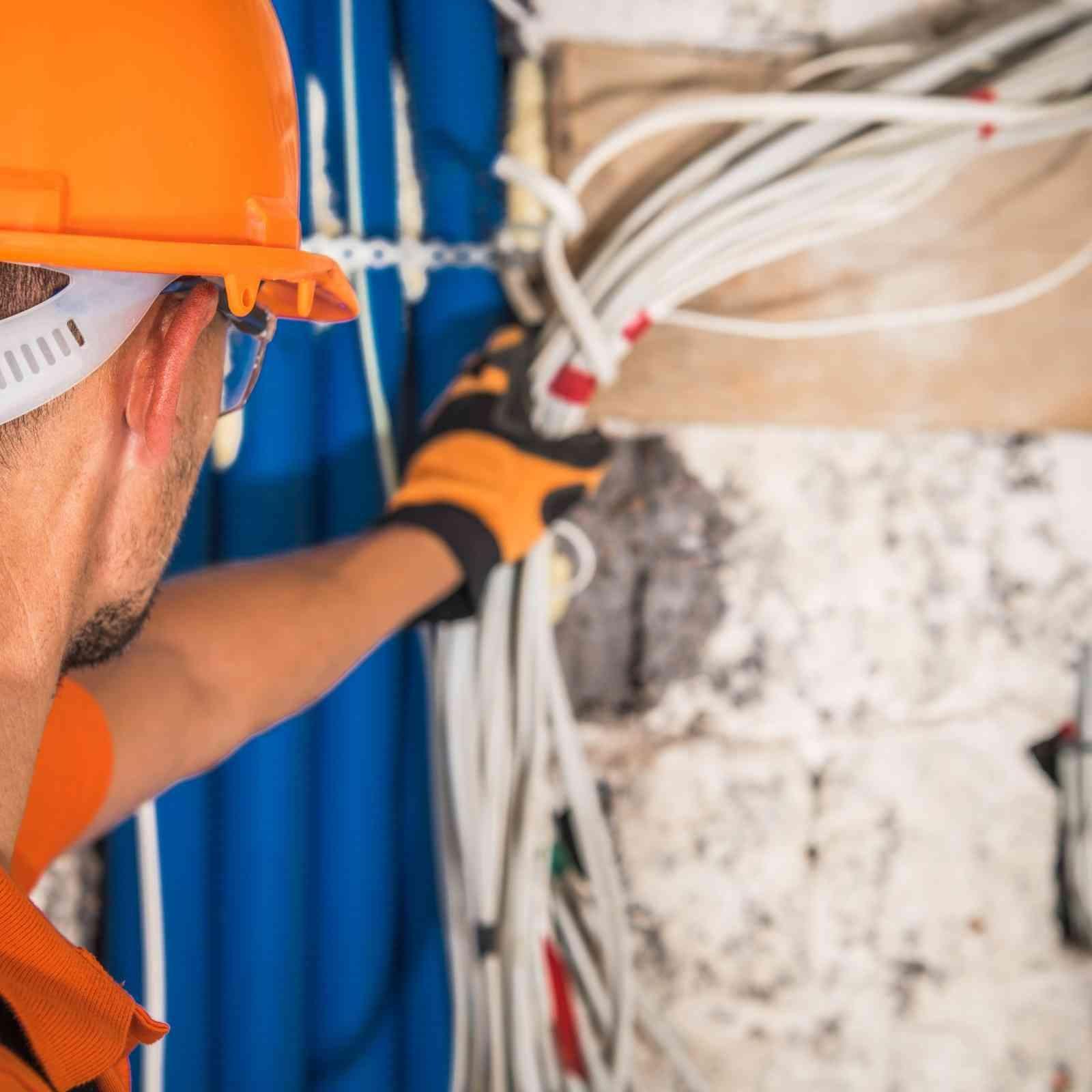

4. Implementation Phase

Installation: Install the fan according to technical specifications and design plans, ensuring all parts are securely and effectively fixed to avoid noise and vibration.

Ductwork Installation: Install the necessary ducts to direct air to and from the fan. Use insulation around ducts if the fan extracts hot or humid air to prevent condensation.

Electrical Connections: Connect the fan to the electrical supply following safety standards. Install switches or control systems as needed.

Testing and Commissioning: Test the fan to ensure it operates efficiently and all components are correctly installed.

Ventilation systems include several fundamental components:

Air Intake Units

Purification Units

Air Heaters

Fans

Air Duct Lines

Distribution Pipes with Necessary Outlets/Nozzles

Supply and Exhaust Air Vents

Duct Fittings (to connect different pipes and form turns and junctions)