- Exit 15, Eastern Ring Road, Prince Saad bin Abdulrahman Road, Plaza Complex, Second Floor, Office 8

- info@activeguard.site

Exit 15, Eastern Ring Road, Prince Saad bin Abdulrahman Road, Plaza Complex, Second Floor, Office 8

0543804776

info@activeguard.site

by activeGuard

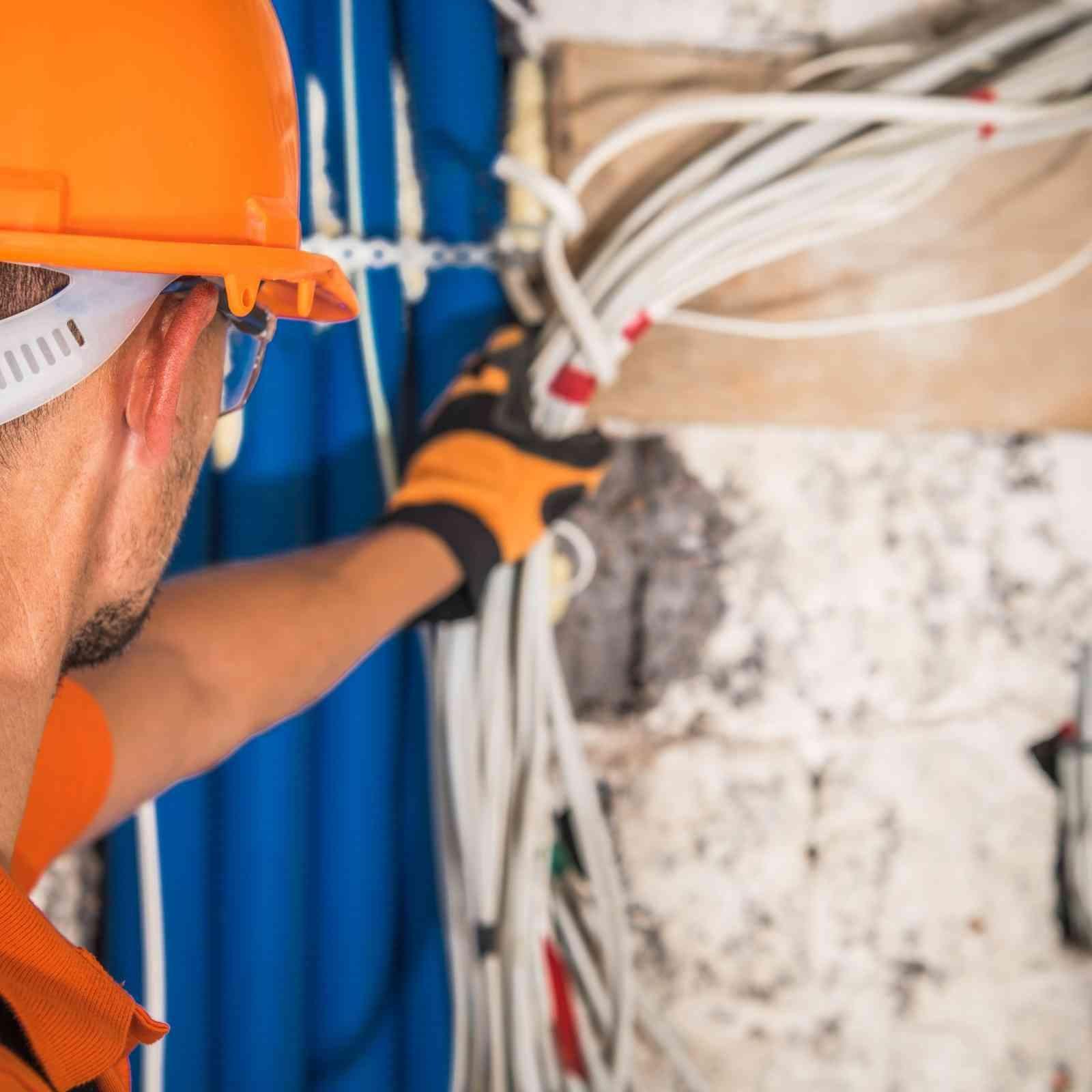

by activeGuard The sprinkler system is one of the most common automatic fire suppression systems, relying on automatically spraying water when the temperature rises. The system consists of metal pipes filled with water or air, connected to heat-sensitive sprinkler heads. When a fire reaches a specific temperature (typically 57-68°C), a fusible element in the head melts, allowing water release.

Design and System Types:

Wet Pipe System: Pipes are always filled with water, suitable for areas with low temperatures. Provides immediate response.

Dry Pipe System: Contains compressed air, used in cold areas to avoid freezing. Upon activation, the air escapes and water enters.

Preaction System: Combines dry and wet systems; requires an additional electrical signal to avoid false discharge.

Sprinklers must comply with UL/FM standards to ensure adequate pressure and flow (approximately 40-60 psi). In large facilities, the system is integrated with smoke alarms for early detection.

Installation and Operation:

Installation begins with a hydraulic study of the building, including water flow calculations (often 150-250 gallons per minute per sprinkler). The system is connected to fire pumps to boost pressure. Operation is fully automatic but requires periodic maintenance every 5 years to inspect pipes and valves.

Advantages and Disadvantages:

Advantages: Effective in suppressing 90% of fires and reduces damage by 50% compared to manual firefighting.

Disadvantages: May cause water damage to sensitive property such as museums.

Clean agents are environmentally friendly alternatives to halons, operating by absorbing heat or reducing oxygen without leaving residue. They are used in enclosed spaces like server rooms or offices. According to NFPA 2001, the gases must be non-toxic and non-conductive.

FM200 (HFC-227ea):

FM200 is a non-combustible heptafluoropropane gas, stored as a liquid and released as a gas. It acts quickly (10 seconds) by absorbing heat, lowering the temperature below 100°C. Suitable for fire classes A, B, and C.

Design: Consists of storage cylinders, distribution pipes, and discharge nozzles. Typical dosage is 7-9% of the room volume.

Installation: Requires an airtight room for 10 minutes after discharge. Integrated with alarm systems for automatic evacuation.

Maintenance: Annual inspection for pressure and leaks, with recharging every 5-10 years.

Advantages: Does not affect electronic equipment, allows immediate return to work.

Disadvantages: Relatively costly (approximately $50,000-$100,000 for a medium system).

NOVEC 1230:

NOVEC 1230 is a non-flammable fluoroketone liquid that vaporizes upon discharge. Considered more environmentally safe than FM200 due to not harming the ozone layer. Used in sensitive facilities like data centers.

Design: Dosage of 4-6%, works by rapid fire cooling. Compatible with FM Global standards.

Installation: Similar to FM200 but requires precise humidity calculations to avoid condensation.

Maintenance: Inspection every 6 months, with focus on handling safety due to its high boiling point (49°C).

Advantages: Non-toxic and dissipates within minutes without residue.

Disadvantages: Higher recharge cost compared to FM200.

The CO2 system relies on releasing carbon dioxide gas to reduce oxygen levels below 15%, thereby suffocating the fire. Suitable for classes B and C, such as engine rooms or warehouses.

Design: High-pressure cylinders (850 psi), with automatic or manual release valves. Stored as a liquid and released as a gas.

Installation: Requires good ventilation after discharge to prevent asphyxiation. Dosage is 34-50% of the protected volume.

Operation: Activates at 68°C or upon an alarm signal. The effect lasts for minutes.

Advantages: Effective and electrically non-conductive.

Disadvantages: Hazardous to human life if evacuation is not ensured; therefore used in unoccupied areas. Installation must follow NFPA 12.

The foam system combines water and chemicals to produce foam that covers the burning surface, preventing oxygen access. Ideal for liquid fires (Class B) such as fuels or oils.

Design: Foam types include AFFF (Aqueous Film Forming Foam) and AR-AFFF (Alcohol-Resistant). Consists of foam tanks, pumps, and foam makers/dischargers.

Installation: Integrated with water pipes, with calculations for foam concentration (1-6%). Suitable for airports and refineries.

Maintenance: Inspect tanks every 3 years, test foam to ensure it hasn't deteriorated.

Advantages: Cools and covers the surface effectively.

Disadvantages: May require cleanup after use; not suitable for electrical fires.

Fire pumps are essential for providing adequate water pressure in other systems. They operate automatically when pressure drops.

Types: Electric (for daily use), Diesel (for emergencies), and Vertical Turbine for high pressure.

Design: Compliant with UL/FM, with a flow of 500-2000 GPM and pressure of 100-150 psi. Includes backup engines.

Installation: In a separate room, connected to water sources. Operation is automatic via pressure sensors.

Maintenance: Weekly testing for diesel pumps, annual inspection for electric pumps.

Advantages: Ensures reliable flow.

Disadvantages: Diesel pumps require backup fuel.

Conclusion

Automatic fire suppression systems form the first line of defense against fires, and their selection depends on the type of facility. It is advisable to adhere to international standards to ensure effectiveness. For consultation, contact certified professionals.