- Exit 15, Eastern Ring Road, Prince Saad bin Abdulrahman Road, Plaza Complex, Second Floor, Office 8

- info@activeguard.site

Exit 15, Eastern Ring Road, Prince Saad bin Abdulrahman Road, Plaza Complex, Second Floor, Office 8

0543804776

info@activeguard.site

by activeGuard

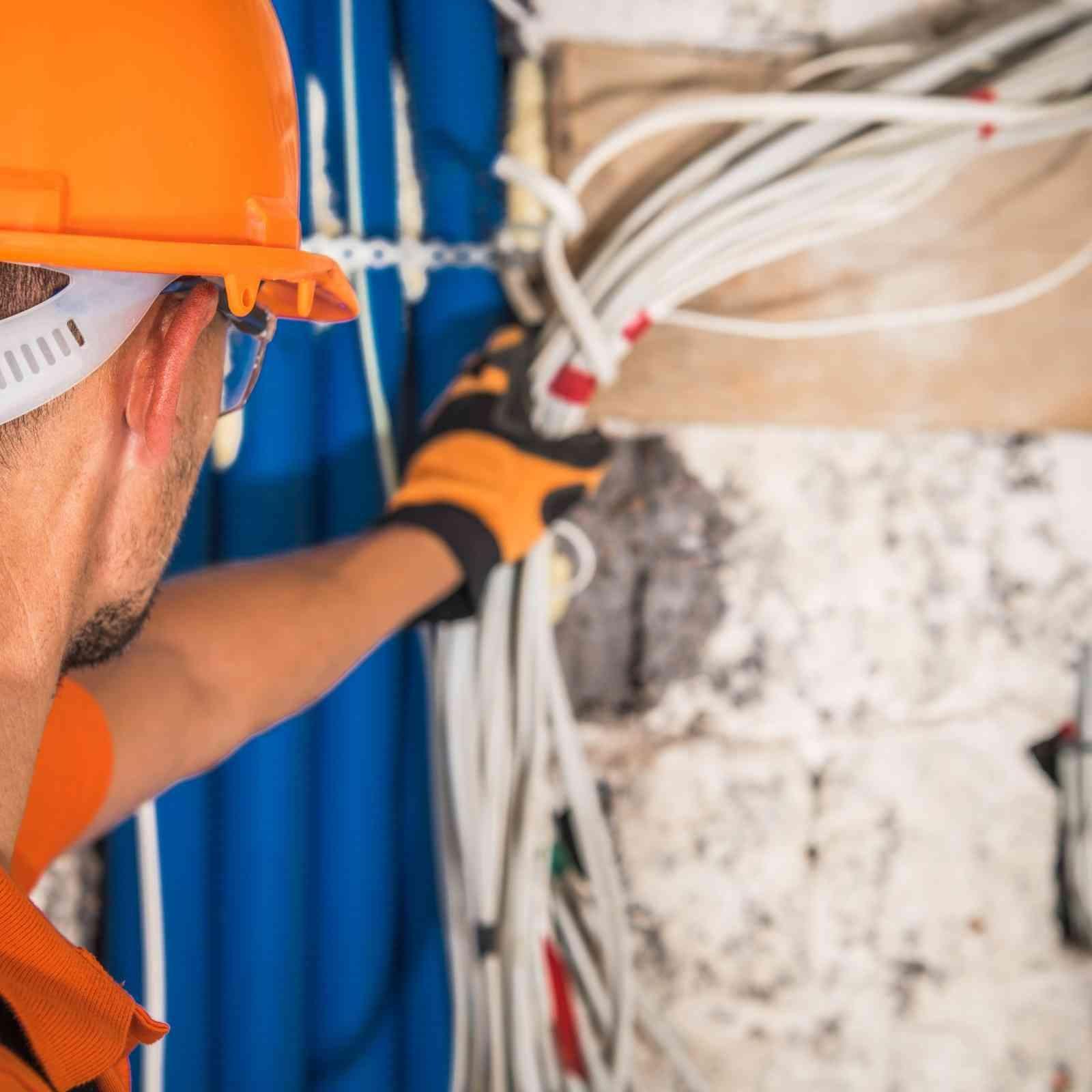

by activeGuard The sprinkler system is considered one of the oldest and most common and effective automatic fire suppression systems. This system consists of a network of pipes filled with water (in wet systems) or compressed air (in dry systems), equipped with strategically placed sprinkler heads. Upon fire detection and when the temperature rises to a specific threshold, the sprinkler heads closest to the fire source activate, causing water to spray directly onto the flame area. These systems ensure a rapid response to fire, helping to suppress up to 90% of fires before firefighting teams arrive.

Types:

Wet Pipe Sprinkler System: Pipes filled with water and ready to discharge when the temperature rises.

Dry Pipe Sprinkler System: Pipes filled with compressed air; the air is released upon fire detection, allowing water to flow.

Pre-Action System: Combines features of wet and dry systems and requires a signal from an additional fire detection system before water enters the pipes.

Rack Sprinkler System: Specifically designed for multi-tiered warehouse shelving, with sprinklers installed at each level to ensure effective coverage.

These systems are used in areas that require protection without leaving any residue after extinguishment, such as data centers, server rooms, laboratories, museums, libraries, and hospitals. Clean agents work by reducing the oxygen concentration or absorbing heat from the fire area, stopping the combustion chemical reaction without damaging sensitive equipment or the environment.

FM200: An effective and fast-acting extinguishing gas that works by absorbing heat from the fire. Widely used to protect spaces containing valuable electronic equipment.

NOVEC 1230: Considered a newer generation of clean agents, stored as a liquid and converting to gas upon release. It is environmentally friendly, evaporating quickly without leaving any residue.

Carbon dioxide (CO2) is an effective extinguishing agent for Class B (flammable liquids) and Class C (electrical) fires. CO2 works by lowering the oxygen concentration in the air surrounding the fire, thereby suffocating the flames. Since CO2 is a non-conductive gas, it is suitable for protecting electrical equipment. However, its use in enclosed spaces requires precautions to ensure personnel safety, as reduced oxygen levels can be dangerous.

Foam systems are primarily used to extinguish Class A (solid materials) and Class B (flammable liquids) fires, especially in industrial applications such as oil refineries, fuel storage facilities, and airports. The foam works by covering the surface of the burning material, preventing oxygen access, cooling the material, and preventing the evaporation of flammable liquids.

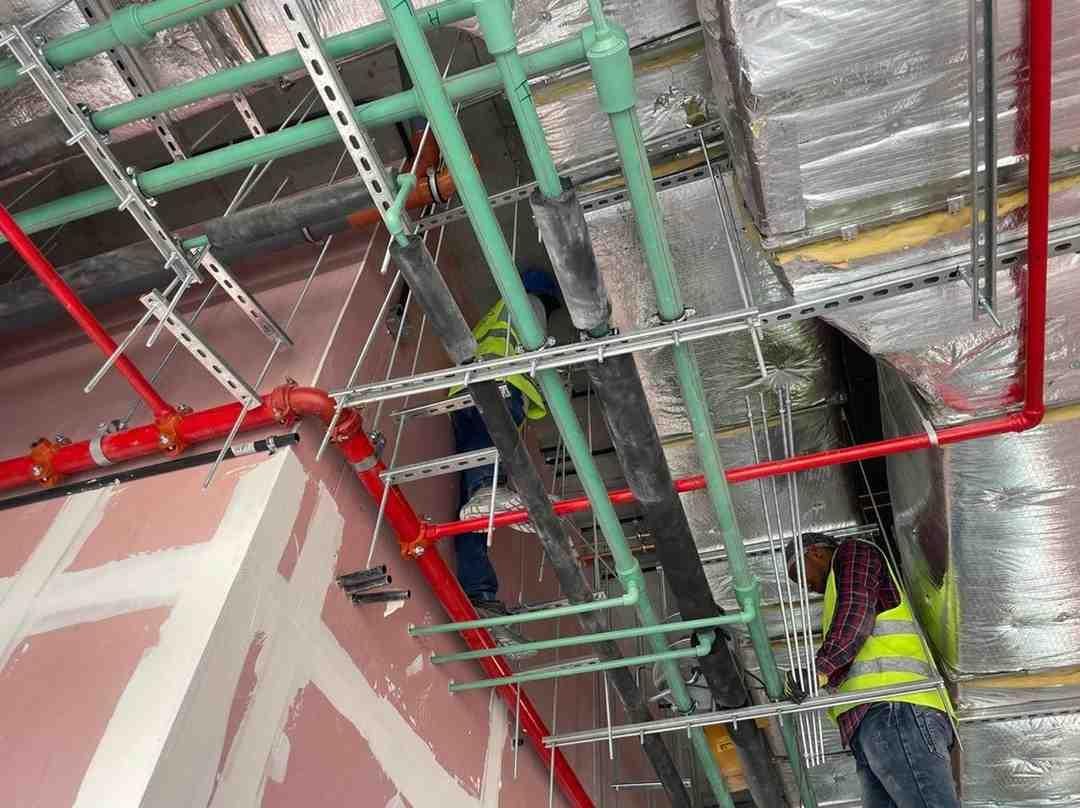

Fire pumps are a crucial component of firefighting systems, ensuring an adequate and continuous water pressure supply for the fire suppression network, such as sprinklers and fire hydrants, especially in buildings without a high-pressure water supply. These pumps increase water pressure to provide the required flow for effective fire suppression. They are available in various types, including electric and diesel, to meet different application needs.

The aforementioned safety systems and equipment are essential to ensure:

Life Protection: Providing a safe environment and reducing the risks of injury or death due to fires.

Property Preservation: Minimizing material losses caused by fires and protecting valuable buildings and equipment.

Business Continuity: Reducing operational downtime resulting from fires and ensuring the continuity of services in vital facilities.

Regulatory Compliance: Meeting the requirements of Civil Defense and international standards such as NFPA, ensuring the safe operation of facilities.

The appropriate safety system must be selected based on the nature of the facility, potential risks, and environmental requirements, in consultation with specialized experts to ensure the effective installation and maintenance of these vital systems.